HYGIENISATION AND GRANULATION OF SEWAGE SLUDGE

The proposed system is used for full hygienization of sewage sludge using quicklime. In this process, a sanitizing agent is primarily the high temperature and the second one is highly alkaline reaction of the substances.

During the lime and sludge treatment temperature can reach and even exceed 100 ° C. While mixing the reaction occurs of quick lime (CaO) with water in the sludge. This reaction produced hydrated lime Ca (OH) Ї and thermal energy.

One of the important factors that influence on the process of liming is the chemical and physical characteristic of lime. The particle size may influence the rate of hydration and thus the time required to obtain the pasteurization temperature. Hydration involves mixing lime with a quantity of water with which a lime is a dry powder. The product can be packaged and exported from the area of treatment.

As a result of the technological process in the proposed installation the end product will have the properties of soil improver.

The whole system is fully automated. High temperature process guarantees full hygienization.

Capacity and plant size is scaled to fit the production of sludge in the WWTP.

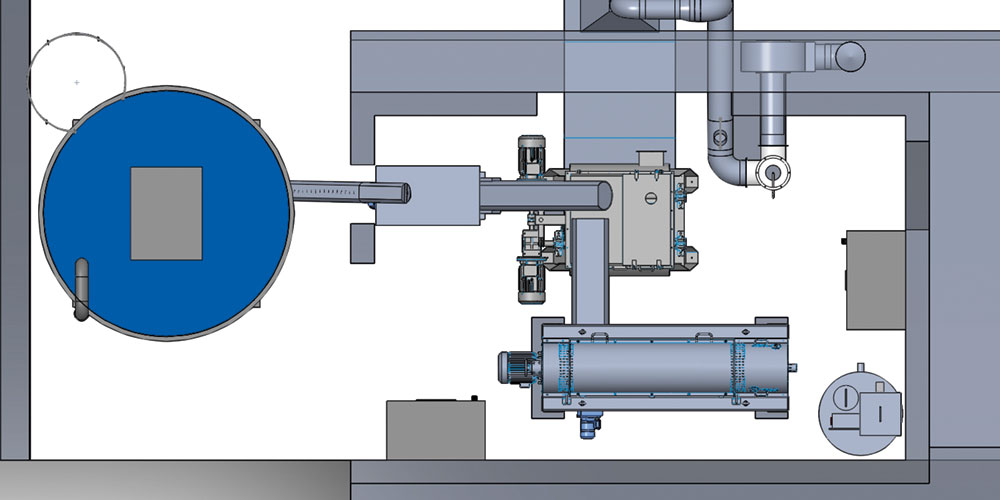

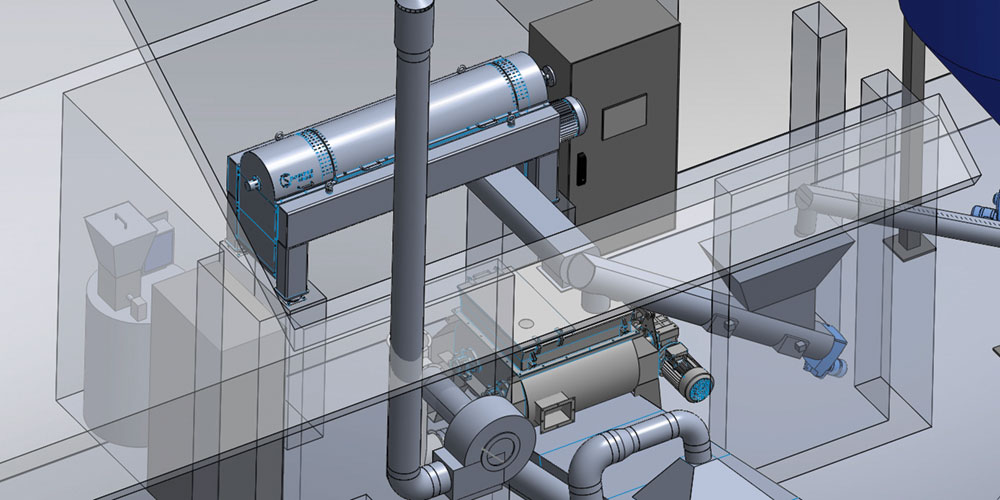

The main devices in the path of processing the solid fraction are:

- Sludge conveyor,

- Lime silo,

- Lime conveyor with dosing system,

- Lime and sludge granulating reactor,

- Tunnel reactor.

The processing path of the gaseous and the liquid fraction are:

- Extraction system of water vapor,

- Scruber,

- Radial exhaust fan.

All process equipment will be connected with the automation system and controlled on the basis of algorithms obtained after identification and optimization of the process. Identification and optimization of the hygienization process of the sludge will be carried out during start-up. All process devices are connected and controlled by the automation system.